On March 8th, the third phase of the technical renovation project of China Minmetals Salt Lake Yiliping Lithium Project was successfully completed and put into trial operation, marking a major breakthrough in the world's first salt lake brine adsorption industrialization project. As the technical service provider for the core process section of this project, Jiuwu High tech injects technological momentum into this milestone project with its solid and reliable "adsorption+membrane" integrated technology, helping China's salt lake lithium extraction technology move towards a new stage of "high efficiency, low carbonization, and intelligence".

World's first technology to overcome bottlenecks

This technological renovation project adopts the "Efficient Lithium Extraction Technology from Raw Brine" independently developed by China Minmetals Salt Lake. Through the innovation of adsorption process, the comprehensive lithium yield has been increased by nearly 100%, and the production cycle has been significantly shortened. It is expected to increase the annual production capacity of lithium carbonate by 15000 tons. As a key support for the industrial implementation of this technology, Jiuwu High tech has been deeply involved in the entire process of technology verification:

Full cycle technology empowerment

We provide process package development support throughout the entire process, from laboratory parameter optimization, pilot plant validation to industrial scale design.

Breakthrough in core materials

Customized research and development of specialized adsorbents suitable for high sodium lithium ratio brine, with a cumulative loading capacity of 1710m ³ (accounting for 75% of the total adsorption section).

Process system integration

Complete the full process design of membrane separation system and construct an adsorption membrane coupled lithium extraction technology system.

The spirit of the iron army in the extreme cold battle forges exquisite products

Faced with the extremely cold environment of -20 ℃ and the strict requirements for completion before the Spring Festival, the Jiuwu team demonstrated its hardcore execution ability:

Day and night battle: Establish a special task force to work 16 hours a day, setting a new benchmark for adsorbent loading efficiency in the industry.

Smart construction: Adopting modular pre filling technology to overcome the problem of solidification of auxiliary materials during winter construction, with a 100% compliance rate for key parameters.

Full process escort: dispatch process experts to conduct on-site debugging to ensure that the adsorption section passes continuous operation testing in one go.

Collaborative innovation and co shaping of a new benchmark in the industry.

As a long-term technical partner of China Salt Lake, Jiuwu High tech has always adhered to the cooperation philosophy of "technology first, service support":

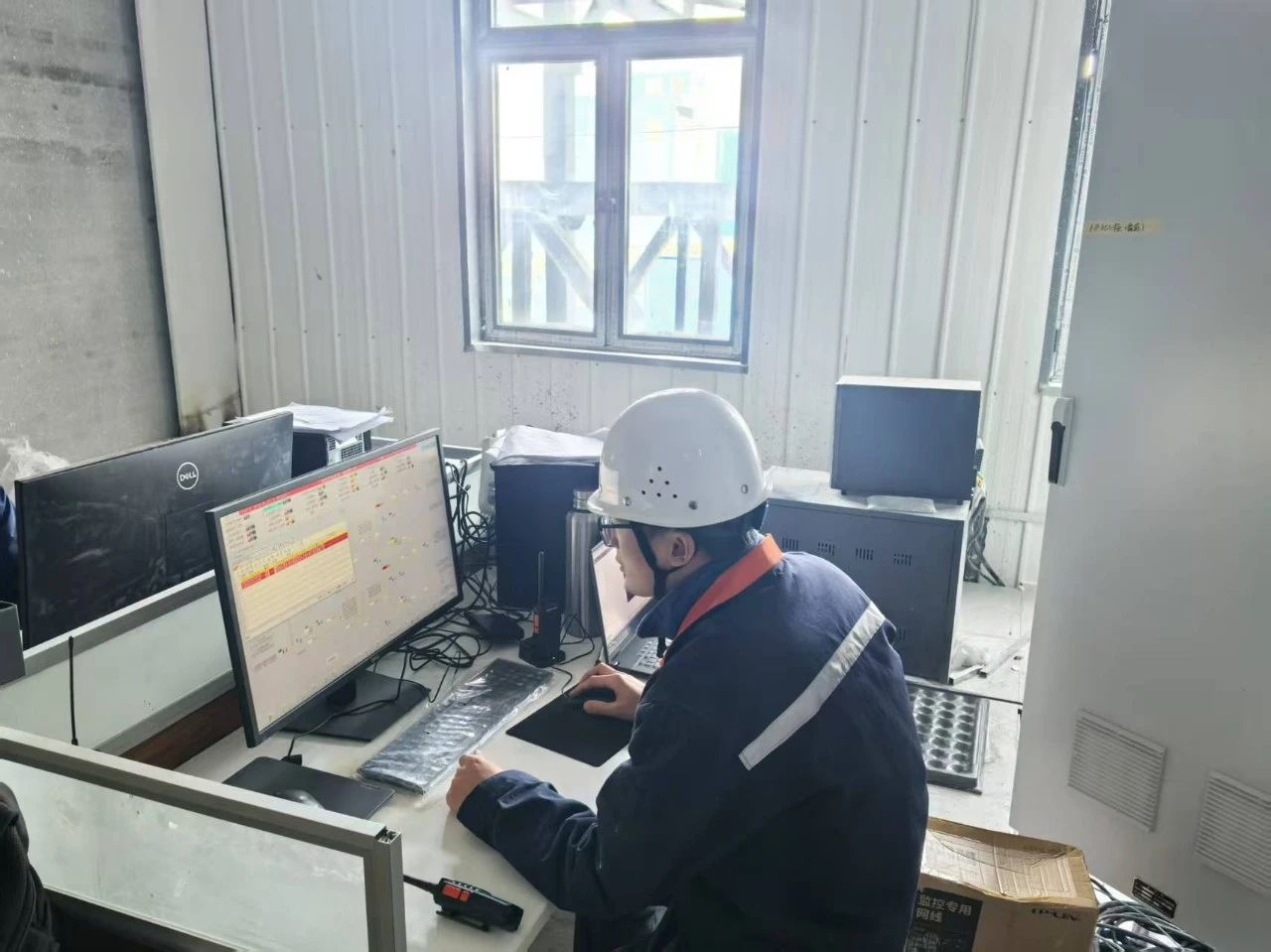

Process optimization: Participate in the design of the lithium extraction process route and parameter optimization throughout the entire process. Intelligent control: Develop automated control solutions to ensure stable operation of industrial production. Low carbon design: By optimizing the energy efficiency of membrane systems, it supports the achievement of clean production goals.

From Cha'erhan to Yiliping, from thousand ton pilot testing to ten thousand ton mass production, as one of the few domestic providers who have mastered the core materials, process technology, commissioning, installation, and operation of the "adsorption+membrane" method for salt lake lithium extraction, Jiuwu High tech will continue to provide in-depth services for upgrading salt lake lithium extraction technology. In the future, we will continue to work together with China Salt Lake to promote the transformation of resource development models through technological innovation, and contribute our wisdom to building a world-class salt lake industry base!

Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808