In the process of upgrading the global titanium dioxide industry, the large-scale production of ultrafine titanium dioxide (particle size 10-50nm) faces a key bottleneck - traditional water washing processes are difficult to balance the interception of nanoscale particles and efficient washing. The organic tubular membrane system independently developed by Jiuwu High tech provides a reliable solution for the industry with verifiable technical indicators and project evidence.

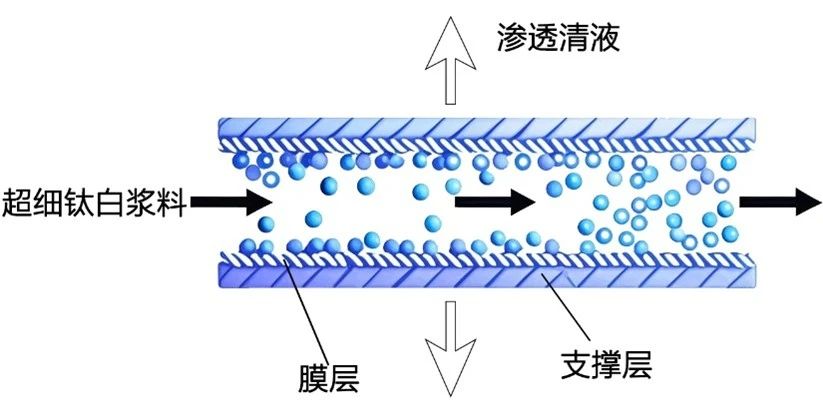

Cross flow filtration to remove soluble impurity ions

The filtration method of tubular ultrafiltration membrane is "cross flow filtration". Under pressure, titanium dioxide slurry flows on the inner surface of the membrane tube, and water-soluble impurity ions accompany water to seep out of the tube along the vertical direction of the membrane tube wall. The solid titanium dioxide is intercepted and circulated inside the membrane tube. By continuously introducing desalinated water and extracting washing water, the purpose of removing soluble impurity ions from the slurry is achieved.

Technological breakthrough: Accurately solving industry pain points

For ultrafine titanium dioxide slurry with strong acidity and high concentration ion content, Jiuwu tubular membrane system achieves breakthroughs through three major technologies:

Precision separation: Designed with a filtration accuracy of 0.02 μ m, it achieves high membrane flux while ensuring a 99.9% retention rate of nanoscale titanium dioxide particles.

Acid resistant reinforcement: A combination of acid resistant modified materials that can withstand strong acid environments (pH 0.5-1) and operate continuously for over 8000 hours.

Stable performance: Multiple batches of washing maintain stable flux and have longer cleaning cycles.

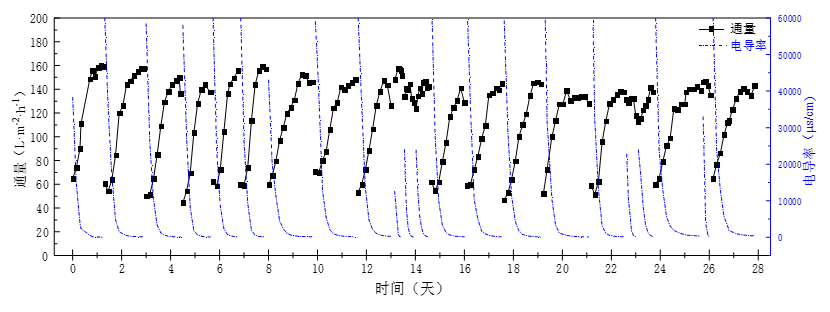

Empirical data: Multi scenario application verification

Compared with traditional membrane filter presses, vacuum leaf filters, and other processes, the tubular membrane process exhibits significant technical advantages in the field of titanium dioxide washing, which are reflected in the following aspects:

1. Improvement of washing efficiency and processing capacity

The tubular membrane adopts cross flow filtration technology, which is more conducive to the separation of impurity ions and titanium dioxide particles. The washing time can be shortened by 8-10 times compared to traditional processes, and the overall processing efficiency is significantly improved.

2. Water conservation

According to different washing requirements of customers, the washing ratio of the tubular membrane process can be controlled at 10-30 times, which reduces water consumption by 50% compared to traditional vacuum leaf filters. Taking the annual production of 1000 tons of high-end ultrafine titanium dioxide as an example, the annual water saving can reach 150000 tons.

3. Avoiding loss of titanium dioxide and economic benefits

Traditional diaphragm filter presses have insufficient filtration accuracy, resulting in a loss rate of up to 5% -8% of nanoscale ultrafine titanium dioxide particles. The tubular membrane can achieve a particle retention rate of 99.9%.

4. Process adaptability and footprint

Modular design reduces the system's footprint by more than 50% compared to traditional processes, making it particularly suitable for old factory renovations or new construction projects with limited space.

Project Case

The following figure shows the on-site continuous operation engineering data of the 500t/a ultrafine titanium dioxide project for the past month. After the washing process of multiple batches of ultrafine titanium dioxide slurry, the membrane flux and washing efficiency remained stable, and no significant downward trend was observed.

Jiuwu High tech Tube Membrane Technology, with verifiable engineering data and economic benefits, promotes the transformation of the titanium dioxide industry from traditional high energy consumption and low efficiency modes to green and efficient. At present, this technology has covered multiple key projects in China. In the future, with technological iteration and large-scale application, tubular membranes will further assist in the upgrading of the global titanium dioxide industry.

Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808