As the first grand event of the spring water treatment industry in South China, the 2025 Guangdong Water Expo will be held from March 5-7 at the Poly World Trade Center Expo in Guangzhou. This exhibition is hosted by the China Membrane Industry Association, the China Instrument and Meter Industry Association, and other organizations. The exhibition covers an area of 36000 square meters, with over 800 high-quality exhibitors covering the three major fields of municipal, industrial, and civilian industries. There are more than 20000 exhibits, and various new technologies, products, and activities are presented in rotation, creating a high-quality water treatment trade platform that integrates buyer meetings, business negotiations, new product releases, summit forums, and other functions.

As a leading enterprise in the ceramic membrane field of China's membrane industry, Jiuwu High tech was invited to participate in this exhibition. R&D engineer Zhang Chun gave a keynote speech on the application of membrane integration technology in the recycling and resource utilization of pulp and paper wastewater, introducing Jiuwu High tech's processes and related cases in the industrial wastewater field.

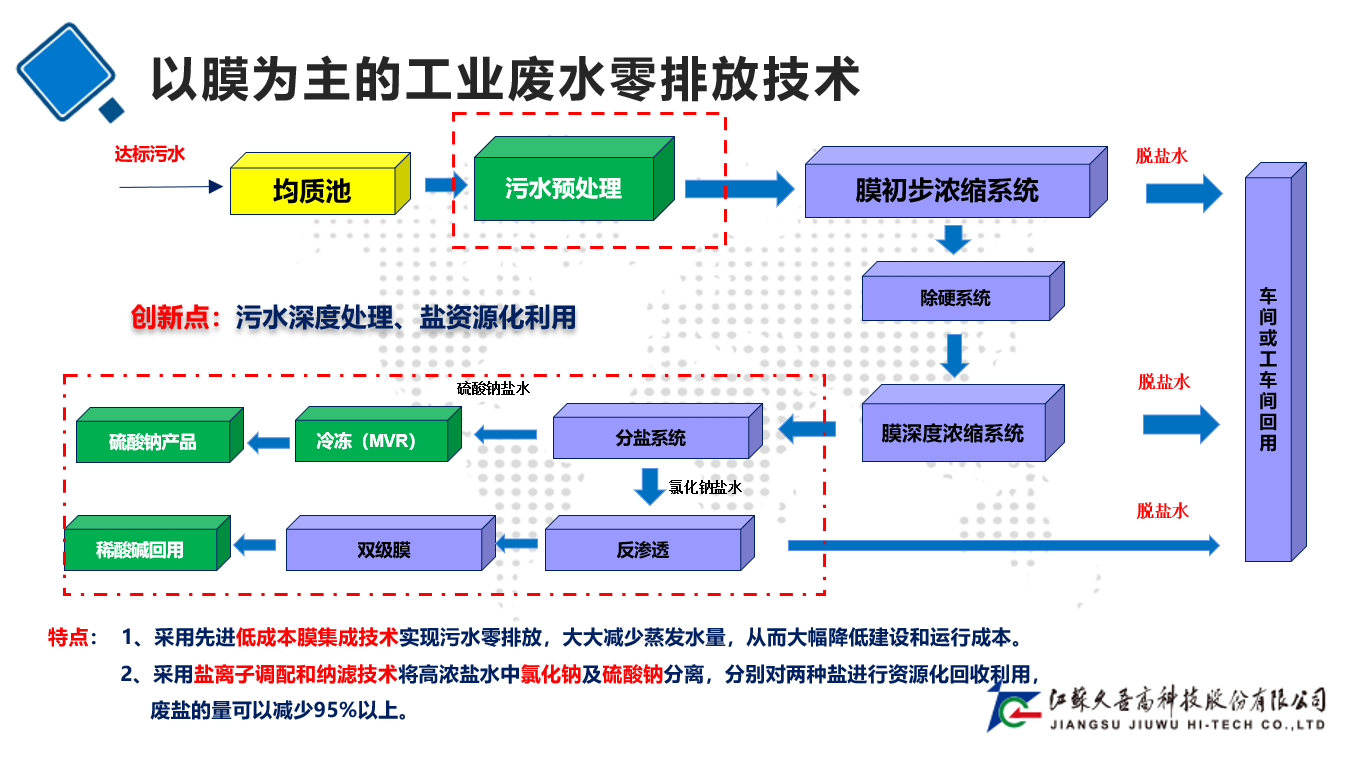

Breaking the traditional zero emission model and reducing construction and operational costs

In recent years, Jiuwu High tech has accumulated rich design and engineering application experience in zero discharge of papermaking wastewater, metallurgical wastewater, and printing and dyeing wastewater, relying on mature and perfect membrane integration technology. Especially in the field of zero wastewater discharge technology, a total of 33 Chinese patents have been applied for, including 7 authorized invention patents. A core patent protection group has been established, including key technologies for the development of special membrane materials, the utilization of waste salt and concentrated salt water resources, and application equipment.

Traditional zero emissions have disadvantages such as high project investment, high operating costs, generation of large amounts of waste salt, high third-party treatment costs for waste salt, which cannot be borne by enterprises and governments, and may even cause serious waste salt pollution.

Compared with traditional zero discharge of wastewater, Jiuwu High tech's membrane based industrial wastewater zero discharge technology adopts advanced low-cost membrane integration technology to achieve zero discharge of sewage, greatly reducing the amount of evaporated water, thereby significantly reducing construction and operating costs; By using salt ion mixing and nanofiltration technology to separate sodium chloride and sodium sulfate from high concentration saltwater, the two salts can be recycled and reused separately, reducing the amount of waste salt by more than 95%.

Industrial wastewater zero discharge technology process based on membrane technology

The superhard process adopts a superhard tank+sodium ion exchange technology, which can control the hardness of the wastewater below 5mg/L; Accurate dosing system, automatically adjusted according to water quantity and quality; SDI<5 after coupling with the membrane.

Double membrane recycling process ultrafiltration unit: Optimize the ultrafiltration operating parameters, adopt reliable operating modes, ensure stable operation of the ultrafiltration membrane system, and extend the service life of the ultrafiltration membrane. Reverse osmosis unit: adopting a two-stage reverse osmosis process to increase the concentration factor of wastewater;

Reverse osmosis concentrated water directly enters the deep softening system;

Adopting mature reverse osmosis technology+material separation approach for control and maintenance+efficient reverse osmosis scale inhibitor to ensure stable operation of the reverse osmosis unit at high hardness. The salt separation unit adopts a patented process combining salt separation and nanofiltration. The fresh water COD content of the salt separation system is low, and the subsequent process system is further concentrated;

The total salt content of the concentrated water in the salt separation system is greater than 100000mg/L (10%), which reduces the processing capacity of the evaporative crystallization system;

After treatment by the salt separation system, the ratio of sulfate to chloride ions in concentrated water is 4.5:1, and in freshwater it is 1:10. High salt concentration unit high-pressure reverse osmosis: The technology is mature, and the roll type membrane has average pollution resistance. It is pressure driven, and the concentration is not high, about 6%. The amount of concentrated water is large, and the subsequent evaporation cost is high. Stacked tube reverse osmosis: Strong anti pollution ability, disc structure, pressure driven, pressure up to 90 to 120 kilograms, high pipeline material requirements, operational safety risks, concentration of about 10%, high investment. Electrodialysis: Driven by electric field force, operating at normal pressure, high safety, high concentration, able to reach 12% -15%, low operating energy consumption, flat membrane structure, strong pollution resistance, can achieve the separation of uncharged organic matter and salt, ensuring the quality of salt output. The wastewater treatment scheme based on membrane and membrane integration technology will be one of the mainstream approaches for future wastewater treatment and emission reduction, injecting technological momentum into achieving the "dual carbon" goal. In the future, Jiuwu High tech will continue to deepen its research and development of membrane technology, accelerate the green transformation of the industrial water treatment field, and help China's water treatment industry move towards a higher level.

Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808